Foam glass gravel

When building a floor over the ground, there are a few factors to consider:

- Insulation against heat loss into the ground,

- Protection against rising damp,

- Stability,

- Overall building statics.

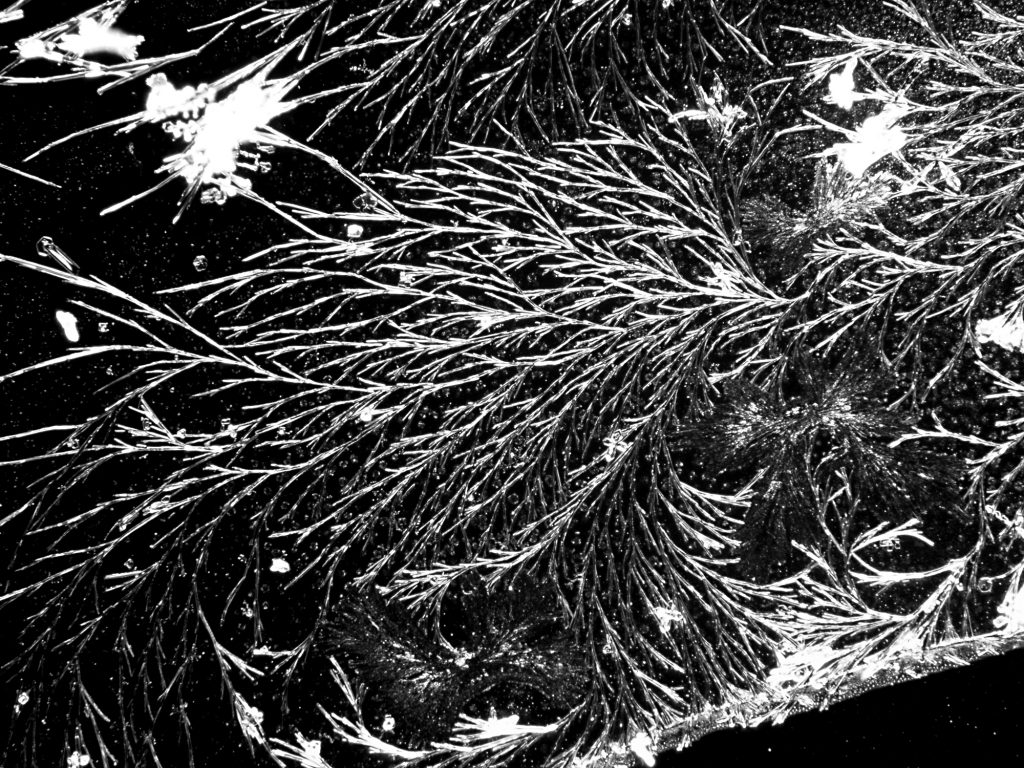

Moisture that rises capillary from below, as it occurs locally to a very different extent, is prevented in ecological building by an approximately 30 cm thick, firmly shaken layer of gravel. It has a capillary-breaking effect and prevents moisture from rising. Rocks that are suitable as crushed stone are lime, washed and broken gravel or, optimally, foam glass. Ballast made of foam glass has the additional property of thermal insulation. It is an inflated, porous glass mineral, made largely from waste glass, which is delivered in big bags as gravel. This bulk material is shaken firmly after being distributed. The vibrated gravel layer is so stable that the floor can be built on it without any problems.

On the gravel

As a rule, a so-called blinding layer lies on top of lime or foam glass gravel, for example a screed made of lime and gravel, a simple rammed earth or even a simple cement screed. On the one hand, this layer facilitates the construction of the following layers, and on the other hand, it enables the direct installation of supply lines such as pipes for wall heating, electrical lines and the like. Ground pipes such as sewer pipes are laid before the ballast and covered by the ballast.

The blinding layer is the basis for the following floor structure. It is common to install counter battens for a plank floor or a screed for a tiled floor.

Lime screed and hemp

In combination with a lime screed, foam glass gravel is so vapor-permeable and capillary-conductive that the building materials can absorb moisture and drain it downwards. Cement-based screed has a significantly lower ability to absorb moisture, and drying is consequently worse. A mixture of screed gravel and an NHL 5 is ideal, simple, inexpensive and ecological.

So that the planks do not lie hollow on the counter battens and every step causes dull noises, the space between them is filled with an insulating material. A hemp-light clay fill, which on the one hand insulates the footfall sound and also acts as thermal insulation, is ideal.

Revitalizing the concrete

If the choice falls on the concrete screed, there is the possibility of enriching it bio-dynamically. In contrast to clay plaster, concrete is a lifeless building material. By adding Pneumatit®, the concrete regains its living structures. The negative effects such as insomnia, irritability, joint pain and exhaustion, which can be caused by the concrete, can thus be prevented.

The concrete additive Pneumatit® is added to the fresh concrete. All the starting materials for Pneumatit® are natural: a range of metals, herbal and mineral homeopathic remedies and much more. Each substance is chosen because it carries certain forces into the concrete, always with regard to people and the world. In total, the production includes around 100 steps over 2 working weeks. The end product, ready for use, has the homeopathic format D7. This is another reason why Pneumatit® does not have any physical or chemical influence on the building material.

To Pneumatit® product